Posted on June-06-2023

Welding has come a long way from its humble beginnings, and today, we stand on the cusp of remarkable advancements and innovations. In this article, we’ll take a closer look at the technologies and trends shaping the future of welding. From automation to augmented reality, let’s dive in and explore the endless possibilities that lie ahead.

One of the most significant trends in the future of welding is the increasing integration of automation and robotics. Robots are revolutionising the welding process by offering improved precision, efficiency, and consistency. They can perform complex welds with minimal human intervention, enhancing productivity and reducing the risk of errors. With advancements in machine learning and artificial intelligence, these robotic welding systems are becoming smarter and more adaptable, further optimising the welding workflow.

Imagine a welding helmet that provides real-time data, overlays digital information on your field of vision, and enhances your welding experience. Augmented Reality (AR) welding helmets are emerging as a game-changer in the industry. They offer welders valuable information such as welding parameters, work instructions, and visual cues, all displayed within their line of sight. These helmets enhance safety, improve accuracy, and reduce the need for external monitors or reference materials.

Laser welding is a rapidly growing field within the welding industry. This technology utilises high-energy laser beams to join materials with precision and speed. The benefits of laser welding include minimal distortion, high welding speeds, and the ability to weld dissimilar materials. As the technology evolves, laser welding is becoming more accessible and affordable, making it an attractive option for various industries such as automotive, aerospace, and electronics.

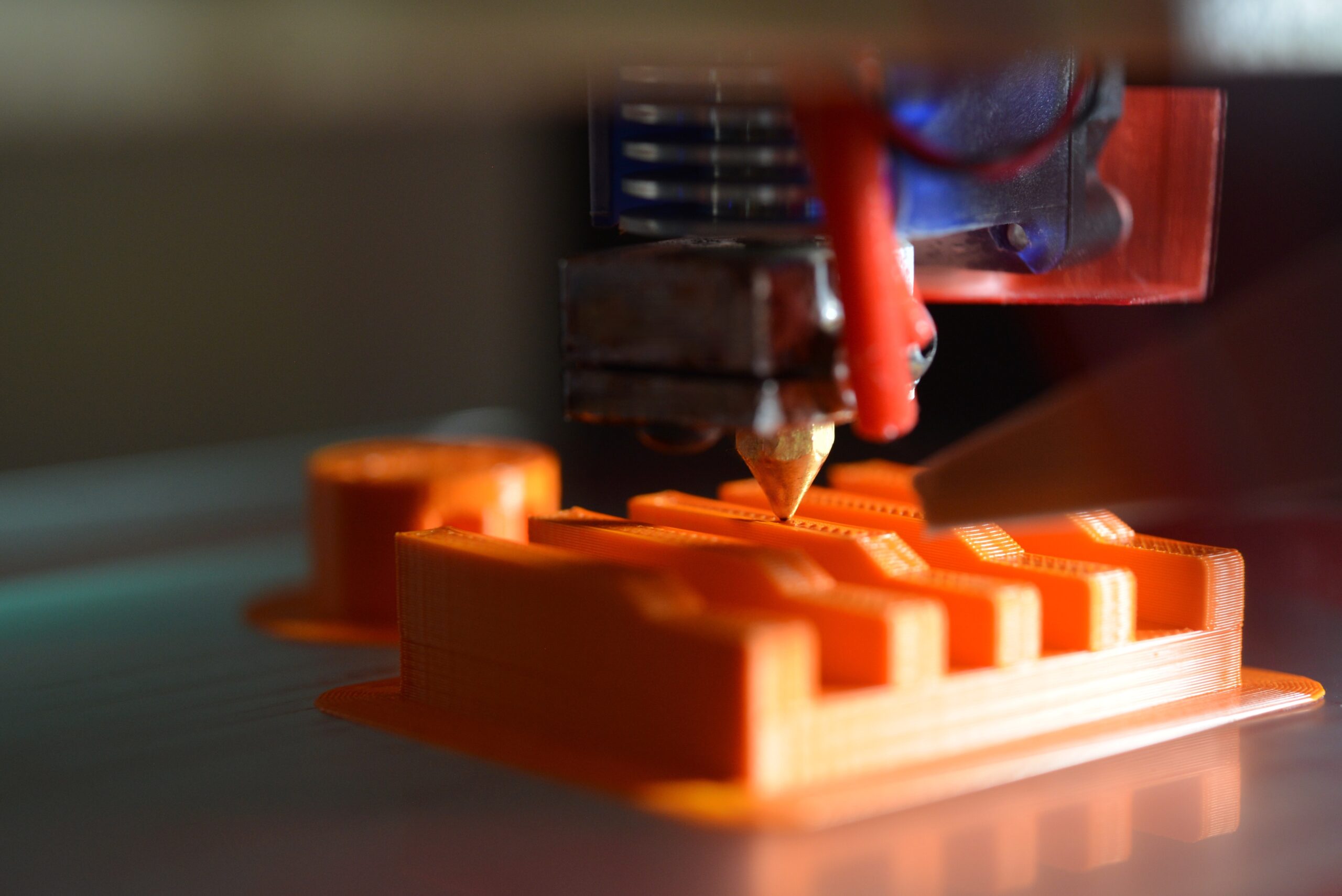

Additive manufacturing, commonly known as 3D printing, is transforming traditional welding processes. It allows for the creation of complex geometries and customised designs, opening up new possibilities for welding applications. By layering and fusing materials, 3D printing enables the production of intricate metal structures with reduced material waste. This technology has the potential to revolutionise manufacturing industries by enabling faster prototyping, on-demand production, and cost-effective part replacements.

In the future, welding will not only focus on traditional materials but also adapt to advancements in new and advanced materials. As industries explore lightweight alloys, composites, and exotic materials, welding techniques are being developed to ensure reliable and efficient joining. Examples include friction stir welding, electron beam welding, and hybrid welding processes. These techniques provide improved strength, durability, and performance in demanding applications.

The future of welding is incredibly promising, with advancements and innovations propelling the industry into new realms of possibility. Automation, augmented reality, laser welding, 3D printing, and advanced joining techniques are just a glimpse of what lies ahead. As technology continues to evolve, welders can look forward to enhanced productivity, greater precision, and safer working environments. At Arc Welding Services, we strive to stay at the forefront of these advancements, providing you with the latest welding equipment and tools to embrace the future of welding with confidence.

While we’ve explored the incredible advancements and innovations that lie ahead, we understand that you may need the right welding equipment now to tackle your projects with confidence. At Arc Welding, we’ve got you covered with a wide range of welding equipment including TIG, MIG, Plasma Machines, welding tools, and supplies.

We provide everything from welding and gas cutting tools to protective equipment and relevant accessories, ensuring that you have all the resources at your fingertips for one-off jobs or ongoing commercial projects.

Get in touch with Arc Welding today by calling us on 0121 327 2249 or filling out our online contact form.