October-10-2025

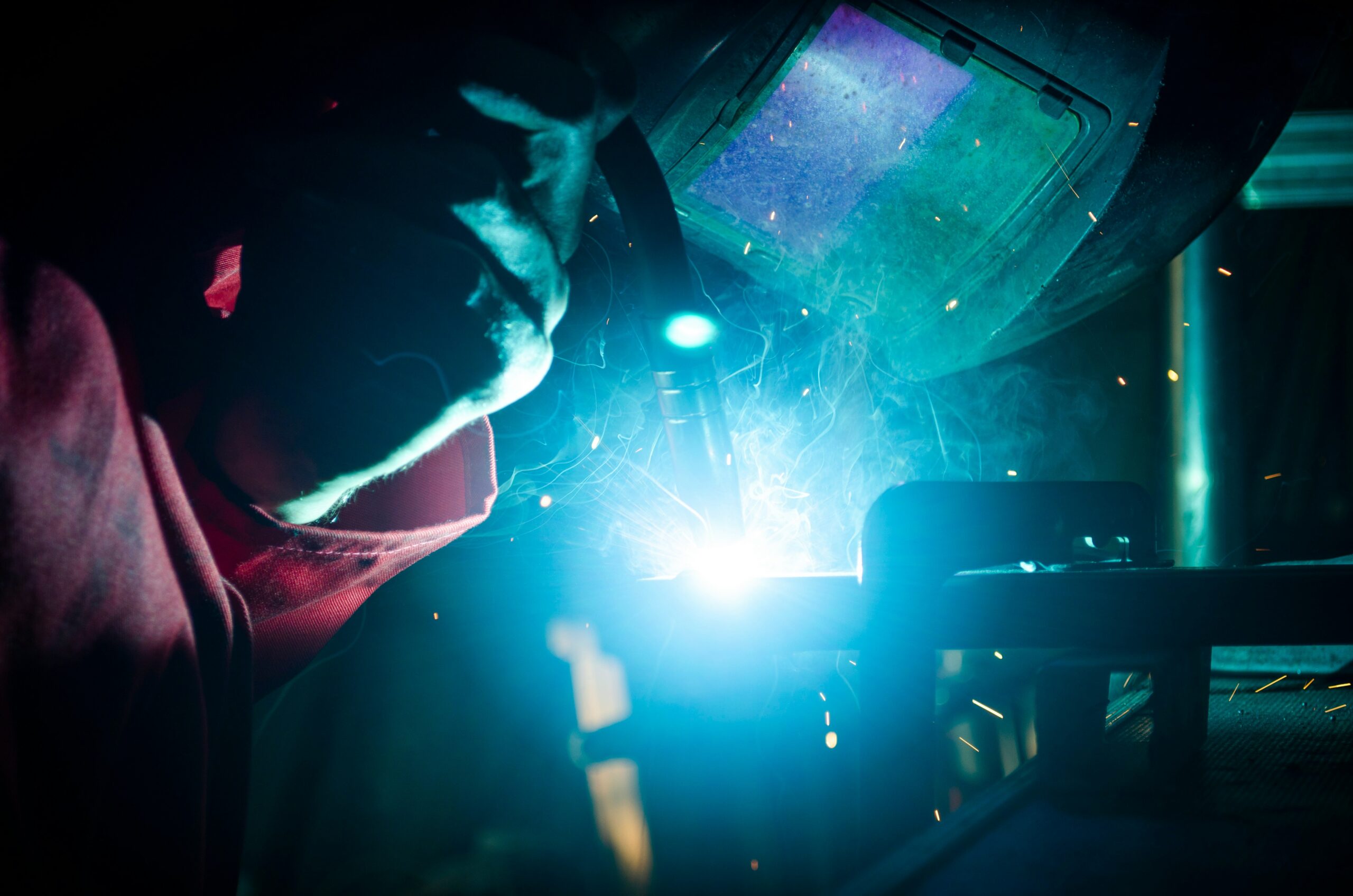

Welding looks easy when you’re watching someone else do it, but anyone who’s picked up a torch knows it’s not that simple. One small slip-up and suddenly you’re dealing with one of those classic welding mistakes messy beads, weak joints, or metal that just won’t hold. Whether you’re just getting started or been at it… Continue reading 10 Common Welding Mistakes (and How to Avoid Them)

October-10-2025

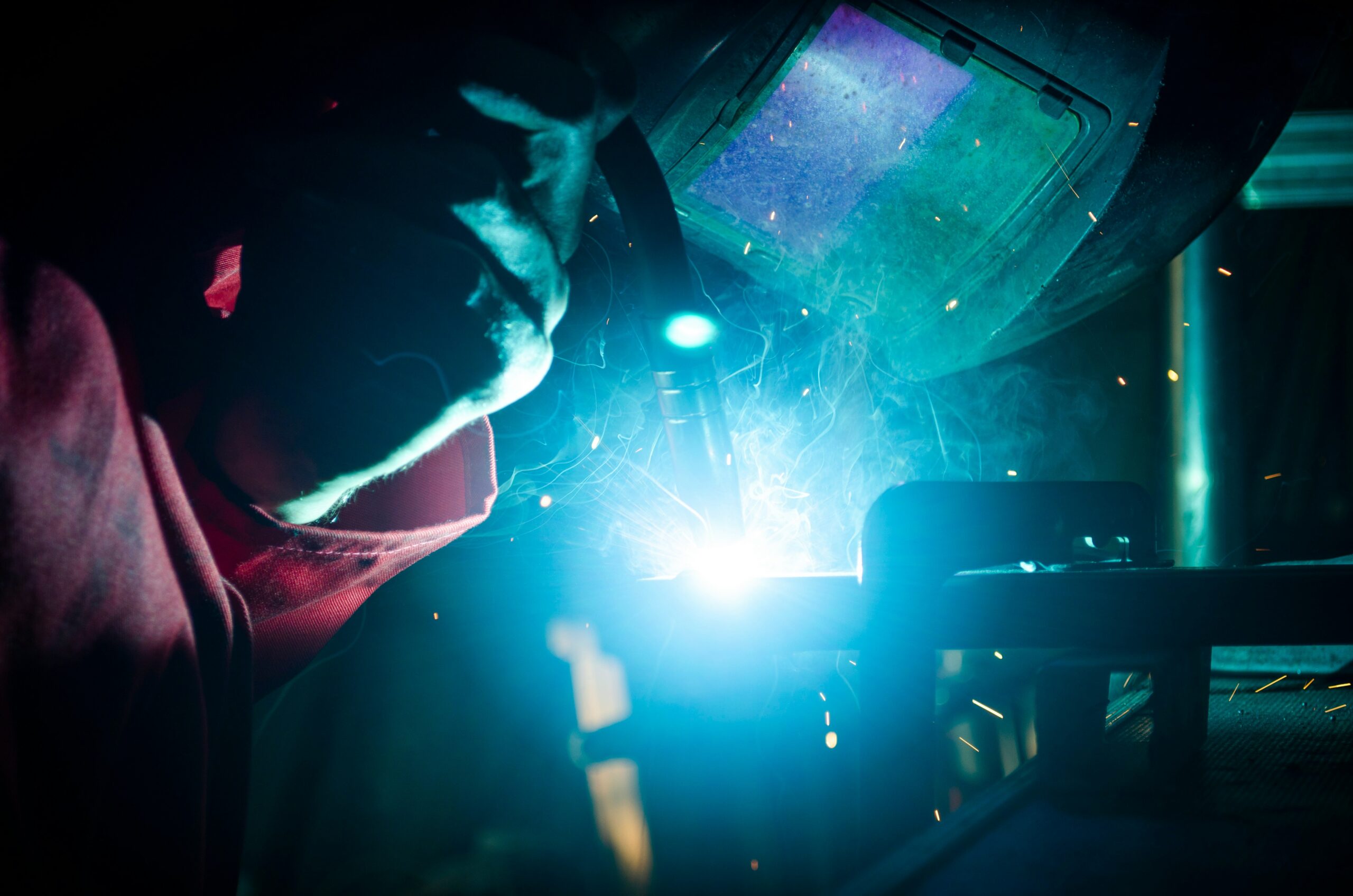

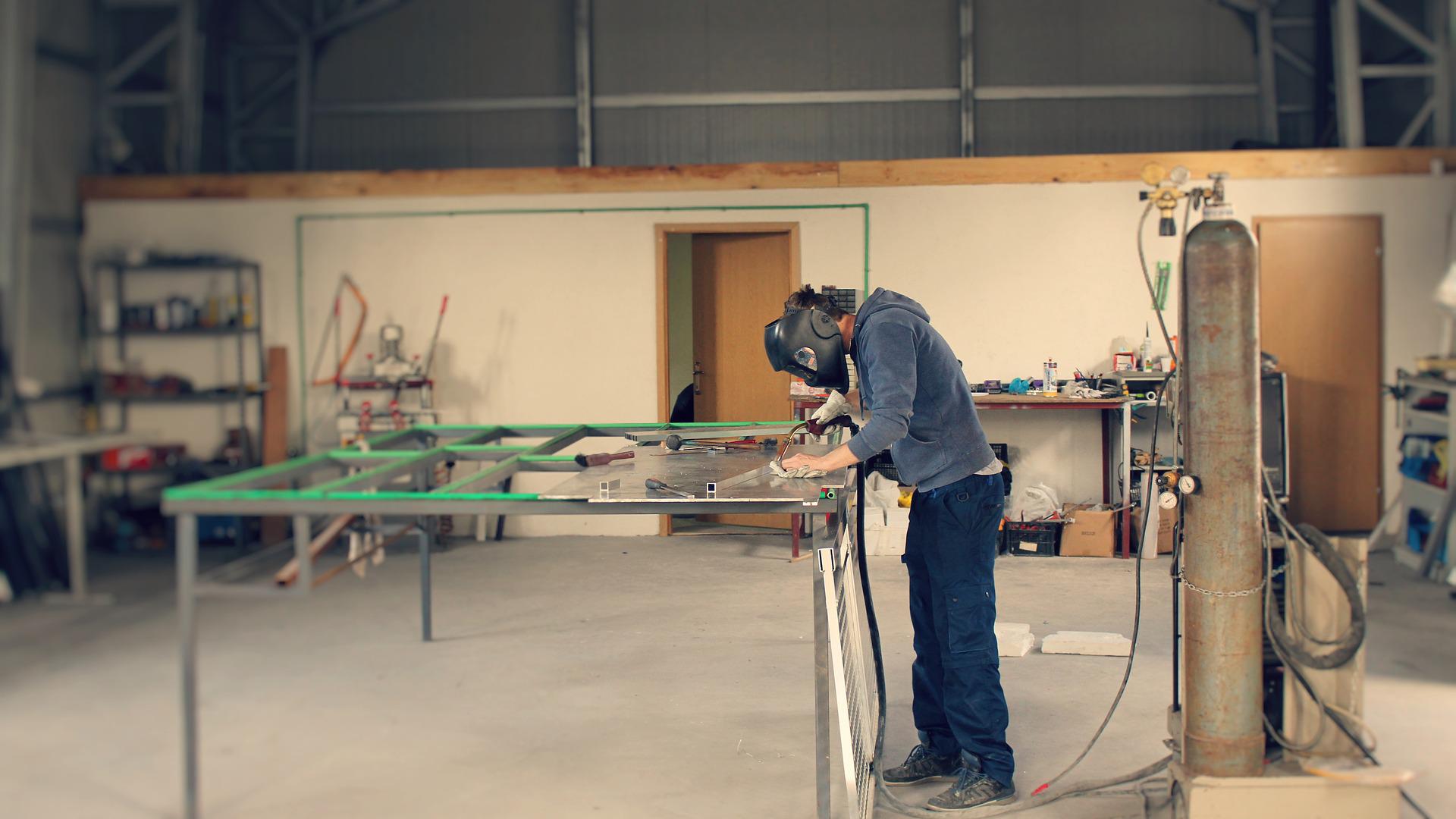

The 4 Main Types of Welding Processes (And When to Use Each One) If you’ve ever stood in a workshop and wondered which welding processes are best to use, you’re not alone. Even expert welders have strong opinions about which method is best. However the truth is that each type of welding process has its… Continue reading What are the 4 types of welding processes?

July-07-2025

Plasma cutting has become a go-to method for cutting metal in a wide range of industries, from heavy fabrication and construction to car repair and even creative metalwork. It’s fast, precise, and surprisingly versatile. If you’ve ever wondered how plasma cutters actually work or why they’ve become so popular, our guide will take you through… Continue reading Simple Plasma Cutting Must Knows

June-06-2025

If you are a welder in your spare time, or if you do welding tasks daily in your career, you may be aware of the importance of plasma cutters in the industry. With the help of us at Arc Welding, we can support your needs by offering a range of tools ourselves. Firstly, it is… Continue reading How Do Plasma Cutters Work – A Welding Machinery Guide?

May-05-2025

Why Is PPE Important? PPE stands for personal protective equipment and is used in welding for various reasons. It is a type of gear/clothing you would wear to protect yourself. This gear is one of the most basic but effective ways to reduce the risk of injury or harm in the workplace. Protective wear acts… Continue reading Why Is PPE Important?

April-04-2025

If you are new to your welding career or far into it, understanding the use of a MIG welder is vital for making your welding day much more manageable. This equipment is a machine using a process called metal inert gas. This technique for welders is great for both beginners and those experienced in the… Continue reading What Is MIG Welding?

March-03-2025

TIG welding, or Gas Tungsten Arc Welding (GTAW), is a welding process that uses a tungsten electrode and shielding gas to create strong, clean welds. It’s commonly used in industries like aerospace and automotive, requiring skill but offering precise results. In this blog, we will cover precisely what TIG welding is, its benefits, and its… Continue reading What Is TIG Welding?

February-02-2025

Nowadays, buying welding gear can cause high operational costs and, over time this could add up. Rising costs of living persuade many people to sell belongings – especially items you may not use often. With manufacturing jobs, it is important to keep the gear you use at high quality to avoid risks. This is where… Continue reading How Hiring the Right Welding Gear Reduces Risk

January-01-2025

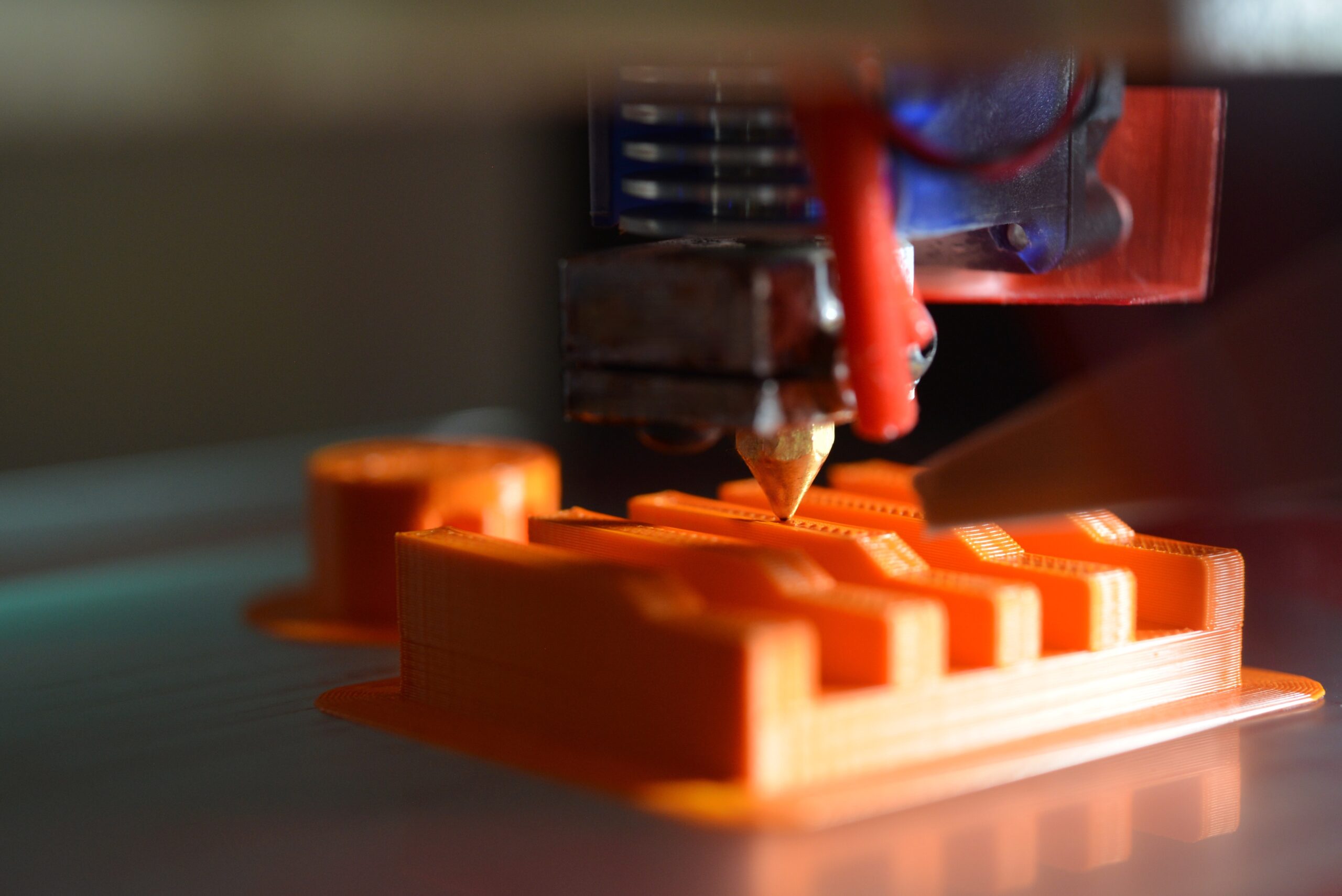

Staying updated is essential for welders to remain competitive and successful in a constantly evolving industry. As techniques, materials, and safety features advance, metal fabrication will be of higher quality, longer lasting, and safer for workers. As new technologies, techniques, and safety standards emerge, welders must adapt to maintain their skills, enhance their precision, and… Continue reading Future of Welding & Innovations to Look Out For

January-01-2025

Fume extractors are a great investment for welders to render solutions to many problems. Without these extractors, the fumes open to our respiratory system, make health conditions more likely to occur in individuals. These could be, lung diseases and respiratory issues all around. As well as this, this trade can come with a lot of… Continue reading Are Fume Extractors Worth Welders Purchasing?

November-11-2024

Welding is an essential process across many industries, creating strong, durable joints that ensure the safety and longevity of structures and components. However, even the most skilled welders can encounter defects that compromise the quality and integrity of their work. Recognising these issues and understanding how to prevent them is key to producing reliable and… Continue reading Common Welding Defects and How to Prevent Them

October-10-2024

When it comes to welding equipment, choosing the right provider can make all the difference in the quality, cost, and success of your project. While many businesses and individuals might be tempted to go with larger, national welding companies, opting for a local welding provider offers a range of unique benefits. Whether you want to… Continue reading Benefits of Choosing a Local Welding Company

September-09-2024

Whether you’re undergoing a DIY project, or you’re part of a team working on a big commercial project, having the right equipment for the job is essential. However, owning a full range of welding equipment can be a costly and sometimes unnecessary investment, especially for short-term projects or those just starting out. That’s where Arc… Continue reading Advantages of Hiring Welding Equipment

August-08-2024

Welding equipment is the backbone of many industrial operations, and keeping it in good working condition is crucial for ensuring safety, efficiency, and high-quality output. However, like all tools and machinery, welding equipment doesn’t last forever. Over time, wear and tear can take its toll, leading to reduced performance, potential safety hazards, and costly downtime.… Continue reading Signs That Your Welding Equipment Needs Replacing

July-07-2024

When it comes to welding, the quality of your equipment can make all the difference. For welders, whether professional or hobbyist, using high-quality welding tools and machinery is crucial for achieving superior results, maintaining safety, and ensuring efficiency. At Arc Welding Services, based in Birmingham, we understand the critical role that high-quality welding equipment plays… Continue reading The Importance of Good Quality Welding Equipment

June-06-2024

When starting on a welding project, whether it’s a small DIY task or a large-scale construction job, one of the critical decisions you’ll face is whether to hire or buy welding equipment. At Arc Welding Services, a leading provider of welding solutions in Birmingham and the surrounding areas, we are here to help you navigate… Continue reading Welding Hire vs. Buying: Which Option is Best for Your Project?

May-05-2024

Plasma cutters are a powerful tool used in metalworking to cut through various conductive materials with precision and efficiency. By employing a combination of electrical energy and compressed gas, plasma cutters create a high-velocity stream of ionised gas, known as plasma, which melts and expels material from the workpiece in a swift and controlled manner.… Continue reading How Do Plasma Cutters Work

April-04-2024

In welding, saving energy means cutting costs and improving efficiency. With rising energy prices, it’s essential to minimise energy use in welding. Ways to save energy when welding include using inverter-based welding equipment for greater efficiency, optimising welding parameters to suit specific tasks, and selecting the most energy-efficient welding process for the job at hand.… Continue reading How to Save Energy When Welding

March-03-2024

Buying your first welder involves understanding your welding skill level, familiarising yourself with different welding processes, and assessing the advantages each process offers to match your specific needs. This can seem daunting at first but can also be exciting! With a huge range of welding processes at your disposal, selecting the perfect welder requires careful… Continue reading What To Know When Buying Your First Welder

February-02-2024

To put it simply, the type of welding equipment you need depends on the welding process you plan to use, which is determined by the materials you’re working with and the specific requirements of your project. For basic and versatile needs, Stick welding equipment is suitable for a wide range of metals and environments. MIG… Continue reading What Equipment Do I Need For Welding?

January-01-2024

As we step into 2024, the welding industry continues to rapidly evolve as it is driven by technological advancements.This year promises exciting developments, from increased automation to new material usage. In our latest blog, we will explore the key trends and innovations shaping the future of welding. Enhanced Automation and Robotics Automation has been a… Continue reading Welding in 2024: Innovations and Trends

December-12-2023

Welding is an industry where your equipment is as important as your skill! The longevity of your welding tools doesn’t just rely on their quality but also on how well you maintain them. In this blog, we will cover the essentials of welding equipment maintenance to help you keep your tools in the best condition,… Continue reading How To Maintain Welding Equipment

November-11-2023

Welding isn’t just reserved for metals. Glass, a brittle and transparent material, can also be joined or repaired using specialised welding methods. If you’ve ever wondered about the different techniques used to weld glass, you’ve come to the right place! In this blog post, we will cover three primary types of glass welding techniques: fusion… Continue reading Types of Glass Welding Techniques

October-10-2023

Working on a project that requires joining metals together? Well, there are a variety of techniques to choose from. Among the most common techniques are welding and soldering. Each of these methods have unique advantages and applications. In this blog, we will take a closer look at both methods to help you gain a better… Continue reading Welding vs Soldering

July-07-2023

Welding is a versatile and essential skill that enables the joining of various materials. However, it is essential to know what welding techniques are needed for each specific type of material. You want to ensure that you are using the right welding technique for your chosen material to ensure a strong and durable weld. In… Continue reading The Best Welding Techniques for Different Materials

June-06-2023

Welding has come a long way from its humble beginnings, and today, we stand on the cusp of remarkable advancements and innovations. In this article, we’ll take a closer look at the technologies and trends shaping the future of welding. From automation to augmented reality, let’s dive in and explore the endless possibilities that lie… Continue reading The Future of Welding: Advancements and Innovations

May-05-2023

Welding can be a dangerous job if proper safety measures are not followed. It involves high heat, intense light, and the use of potentially hazardous materials, which can pose serious risks to welders. In order to prevent accidents and ensure a safe workplace, it is essential for welders to follow strict safety guidelines and best… Continue reading Welding Safety: Essential Tips and Practices for a Safe Workplace

March-03-2023

The cost of everything is going up – how many times in the past few months have you heard this? It is a harsh reality that at the moment, money is tight for a lot of us. In the professional world, production costs are increasing and manufacturers are always trying to find ways of lowering… Continue reading Why Rent Welding Equipment?

February-02-2023

There are many different ways to cut metal, with some methods being more effective than others. Plasma cutting is a high-tech method of cutting metal and uses ionised, focused jets of gas to cut through thin sheets of metal.When a plasma cutter is switched on, high-voltage electrode quickly heats a compound gas mixture. To focus… Continue reading Is A Plasma Cutter Worth Buying?

January-01-2023

Friction welding is a type of solid state welding and is an umbrella term that encompasses several types of welding processes. It is fast, efficient and one of the most popular types of solid state welding. Friction welding involves generating heat through friction force of the workpiece. The heat generated is so high that it… Continue reading What Is Friction Welding?

December-12-2022

Plasma arc welding involves joining metals together by heating with a constricted arc between the workpiece (transfer arc) and an electrode (non-transfer arc) OR the constricting nozzle and the electrode.The constricted plasma that is formed is highly ionised and concentrated. In simple terms, plasma arc welding uses plasma (gas) that has been superheated to become… Continue reading What Are The Advantages and Disadvantages of Plasma Welding?

September-09-2022

A lap joint is one of the five different types of welding joints. It is most commonly used when joining two different metals that have different levels of thickness. The ‘lap’ reflects the overlapping pattern that is formed when the two metals are joined together. The thickness of the two metals is what determines the… Continue reading What is a Lap Joint Weld?

July-07-2022

If you’ve read our blog on The Science Of Cold Welding, you should have a good understanding of what it is. For those of you who haven’t read it, go take a look for a more detailed explanation of what cold welding is and what it is used for! Whilst cold welding may not be… Continue reading Advantages and Disadvantages of Cold Welding

June-06-2022

The welding profession is one that brings a higher risk of injury compared to others. This is why it is extremely important for workers to ensure that they are using personal protective equipment (PPE). Welders are exposed to extreme heats and powerful equipment daily, so it is vital PPE is taken seriously. PPE exists to… Continue reading PPE in Welding

May-05-2022

Welding is the process of fusing together two or more parts by the means of heat and pressure. Welding is normally used on metals and thermoplastics. The type of welding that is used can depend on a number of factors, but form and thickness of the material is usually the determining factor. As welding and… Continue reading Common Welding Issues: How to Correct Them

April-04-2022

Metal Inert Gas (MIG) is also known as gas metal arc welding (GMAW). This method of welding is simple in comparison to others methods, which explains why it is often the selected method by beginners. This method is an arc welding process that joins two metals with the help of an arc. The arc is… Continue reading MIG Welding

March-03-2022

Welding equipment, bought from new, can be incredibly expensive. A great alternative to this is either renting or buying ex-hire or second hand equipment. We here at Arc Welding Services Ltd. will explore in this blog things that you ought to consider before you invest in second hand equipment including price, quality and durability. Price… Continue reading We Sell Ex-Hire and Second-Hand Welding Equipment

February-02-2022

As our name suggests, here at Arc Welding Services Ltd, we specialise in selling arc welding products and tools. We have the expertise, experience and knowledge to help get you started on your next welding project. One key question we often get asked is, ‘what is arc welding?’ and ‘what are advantages and disadvantages of… Continue reading Advantages and Disadvantages of Arc Welding

January-01-2022

In memory of Terence Harris, we’re running a charity fundraiser in aid of the Anthony Nolan charity (helping save the lives of people with blood cancer). To enter our charity fundraiser, raffle tickets are £5 per strip and you can be in with the chance to win a Samsung Galaxy Tab (32GB); a prize worth… Continue reading Enter Our Charity Fundraiser in Memory of Terence Harris

November-11-2021

What is PAW (Plasma Arc Welding)? Plasma arc welding is a process that is very similar to TIG welding, mainly due to the arc formation that occurs between the pointed tungsten electrode and the workpiece. The main difference between PAW and TIG lies within the positioning of the electrode; with a plasma weld, the arc… Continue reading Guide to Plasma Arc Welding (PAW)

October-10-2021

We love talking about different types of welding in our blog posts, and today is no different. The topic of choice is all about ‘orbital welding’. Let’s start with the basics. What is orbital welding? This type of welding is specialist and involves the arc mechanically rotating 360° continuously around an object (usually a… Continue reading What Is Orbital Welding?

August-08-2021

As with any skill, hands-on training and experience is an important part of learning, especially when it comes to mastering the art of how to weld. If you’re looking for ways that you can improve your welding skills and practice some different techniques, why not take a read of our hints and tips. 4… Continue reading Beginner’s Welding Tips & Tricks

July-07-2021

Repair welding is a popular technique that involves the cracked material being removed by arc gouging and the element welded to re-join the material on either side of the crack. Here at Arc Welding Services, we offer welding machine and equipment repairs, services & calibrations both on-site and in our Birmingham-based workshop. We have decades… Continue reading What is Repair Welding?

June-06-2021

Local exhaust ventilation (L.E.V) is often called dust and/or fume extraction; it can help keep the environment clean before people breathe in these harmful substances. Local Exhaust Ventilation explained… Every year many employees contract occupational asthma and other lung diseases, as reported by The Health and Safety Executive (HSE). These health issues develop because of… Continue reading L.E.V Testing

March-03-2021

Welding is an art. As with any art, colour plays a crucial factor. Welding is no different, and it can produce different colours depending on the type of weld and the metal or material being welded. Often, the colour of the weld can indicate a lot about it. Whilst there are many different and reliable… Continue reading Colours In Welding: What Do They Mean?

February-02-2021

An Overview of Glass Welding Glass welding is most commonly used during the practice of ‘glassblowing’. Glassblowing is a technique that involves inflating and manipulating hot, molten glass into shapes or bubbles using a blowpipe, also referred to as a blow tube. The process of glassblowing is accomplished by heating glass and turning it into… Continue reading What Is Glass Welding Used For?

September-09-2020

Unlike other trades, where you are expected to pass through different hoops and have certain specialist certifications and qualifications before you become a fully qualified tradesperson, the welding industry is a little different. Some employers do ask to see certificates before employing a welder, but this isn’t the norm. Usually, employers are more concerned… Continue reading Differences Between Coded Welders vs. Certified Welders

August-08-2020

What is Submerged Arc Welding? This arc welding process involves the formation of an arc between a continuously fed electrode and a workpiece. This creates a blanket of powdered flux, which helps protect the weld zone. During welding, the arc is submerged beneath the flux blanket and it is not usually visible. This type of… Continue reading Submerged Arc Welding (SAW)

July-07-2020

Plastic welding is a fabrication process, and one that not many people are aware exists. Broken plastics objects can undergo a cosmetic change to bring it back and save it from being thrown away. When we buy something that has plastic coating, and it gets broken, typically we replace it. However, plastic is very malleable… Continue reading Guide to Plastic Welding

June-06-2020

What is Explosion Welding? Explosion welding is achieved by accelerating one of the components at an extremely high velocity through the use of chemical explosives. It is a solid-state welding process that is often used to clad carbon steel with a thin layer of corrosion-resistant material such as stainless steel, nickel alloy, titanium or zirconium.… Continue reading Advantages & Disadvantages of Explosion Welding

May-05-2020

What is Energy Beam Welding (EBW)? Energy beam welding otherwise referred to as electron-beam welding, is a fusion welding process. The method involves a beam of high-velocity electrons that are applied to two materials that are being joined together. The pieces melt and fuse together as the kinetic energy of the electrons is transformed into… Continue reading Guide to Energy Beam Welding

April-04-2020

What is a butt weld? A butt weld is a commonly used welding technique that can be automated or done by hand on steel pieces by a welder. This technique can also be done with brazing copper pieces. Now, you may be thinking, what is a butt welding used for? Well, it is used to… Continue reading What is Butt Welding?

March-03-2020

What is Cold Welding? As you may have suspected from the term ‘cold welding’, there isn’t any heat involved. Cold welding is the process of joining two metals or materials together without using any heat. Now, this may sound impossible and contrary to everything you previously thought you knew about welding. But, it is possible… Continue reading The Science of Cold Welding: How to Join Metals Without Heat

February-02-2020

Advancements Made for Welding Glass to Metal Throughout welding history it was commonly thought that metals could only be welded to other metals, and glass only to glass; the two don’t usually weld together. However, researchers at Heriot-Watt University have developed a new, revolutionary technique that could allow glass and metal to be welded… Continue reading Revolutionary Technique Developed to Weld Glass to Metal

January-01-2020

Underwater welding sounds like a cool and interesting job role. One that involves a great deal of skill and expertise. In a previous blog we explored what is meant by the term ‘underwater welding’ and how you can become an underwater welder. Today, we’d like to focus upon the two different types of underwater welding.… Continue reading How Does Underwater Welding Work?

December-12-2019

From building a laptop computer to constructing a new building, almost anything that is built using metal requires being able to join two metals together. In previous blog posts, we have covered everything from the main welding positions and joints, different types of welding, uses, equipment and PPE. Here, we are going to focus on… Continue reading Difference between welding, soldering and brazing

November-11-2019

The applications of welding are limitless from the aeronautic industry, to automotive to residential needs. Depending on the type of job a welder is carrying out, different types of weld are required. Welding cannot always be done in our most desirable welding position, it all depends on the type of weld required and any joints… Continue reading 5 Different Types of Welding Joints

October-10-2019

Within the welding industry, there are various arc welding processes you can use. The two main processes, and arguably the most well known, are MIG welding and TIG welding. Choosing the right welding process is vital to the success of your project. Using the wrong type of welding technique can result in numerous problems, such… Continue reading Differences between MIG welding and TIG welding

July-07-2019

What is Seam Welding and How Does It Work? Within the welding industry, there are many techniques and processes that come to mind. Specifically talking about ‘seam welding’, we will explore the technique that is used and what the advantages and disadvantages of using this process are. Seam Welding is a different technique used to… Continue reading What is Seam Welding and How Does It Work?

May-05-2019

A Guide to The Different Types of Welding Working with metal can be an impressive skill. Welding requires highly-skilled professionals, who are in constant demand. This skill requires a lot of experience and guidance from professionals within the business. Welding, in all of its forms, simply means the conjoining of two metals and there are… Continue reading Arc Welding Services Ltd – Types of Welding

April-04-2019

The Arc Of Welding Arc welding is a permanent, efficient and economical method, for the joining of two different metals. This process consists of heating localised metals beyond the melting point which then allows the materials to bond. We are going to explore the different methods in which arc welding may be used, the history… Continue reading The Guide Of Arc Welding

March-03-2019

Welding Equipment Repairs: Repair or Replace Sometimes, your welding equipment will require a little care and attention. As very heavy-duty equipment, the tools used for welding are often exposed to extreme temperatures and can face a lot of physical challenges. Here, we explain how to tell the difference between equipment in need of repair and… Continue reading Welding Equipment Repairs: Repair or Replace?

February-02-2019

Fume Extraction Notification There has been an important update from the HSE (Health and Safety Executive), focusing on mild steel welding fume extraction. The directive is relevant for anyone that welds, and is important to take on board for your own safety, as well as others around you. You can read the full directive at… Continue reading Update from the HSE: Fume Extraction Notification

January-01-2019

Welding Health and Safety: The Essentials Welding provides solutions in so many areas of the manufacturing world. It is an extremely useful process that requires years of training and experience to master. As well as being useful, though, it is also potentially quite dangerous. It is absolutely essential that welding health and safety is constantly… Continue reading Welding Health and Safety: The Essentials

December-12-2018

The World’s Biggest Welding Projects from the USA Welding is a broad term that simply refers to the joining of metal parts by using heat. It’s easy to see why so many industries rely on the practice, but sometimes its significance can be overlooked. To underline the potential of welding as a practice, we’ve put… Continue reading The World’s Biggest Welding Projects from the USA

September-09-2018

What Skills Do All Welders Need? Welding is, as we’ve explained in one of our previous blog posts, used all over the place in everyday life. How though, can you get into the industry? In our latest blog, we examine the skills you need if you’re going to become a welder. For questions about our… Continue reading What Skills Do All Welders Need?

August-08-2018

A Closer Look at Some of Our Welding Equipment Here at Arc Welding Services Ltd, we’ve got a great range of welding equipment available for hire. In our latest blog post, we’re taking a closer look at some of that equipment, with a view to explaining what it does and why it’s so useful in… Continue reading A Closer Look at Some of Our Welding Equipment

May-05-2018

Uses of Welding in Everyday Life: a Brief Overview There are a huge number of services and products that rely on welding, in one form or another. Unless you live a particularly sheltered life, you’re probably coming into contact with these all the time. From public transport to theme park rides, welding is a vital… Continue reading Uses of Welding in Everyday Life: a Brief Overview

March-03-2018

How to Store Welding Equipment It is absolutely essential to store welding equipment properly, both from a safety perspective and to ensure the lifespan of your tools isn’t shortened. Here, Arc Welding Services take a look at a few measures you can put in place to ensure your equipment is stored properly, preventing it from… Continue reading How to Store Welding Equipment

March-03-2018

Spring Offer on ESAB Equipment Running from February 21st to June 29th, Arc Welding Services are offering up to 45% off on three products from industry-leading manufacturers, ESAB. Boasting a 3-year warranty, we are giving you the opportunity to purchase the Rebel EMP 215ic, Renegade ES 300i, and the SENTINEL helmet at fantastic discounted prices!… Continue reading Spring Offers on ESAB Equipment from Arc Welding Services!

February-02-2018

The benefits of apprenticeships in welding are well known by employers that work in the industry, but perhaps not so clear for those evaluating their options for post-16 education. What is clear, though, is that an apprenticeship is a great opportunity to kickstart a career in welding. Here at Arc Welding Services, we have a… Continue reading The Benefits of Apprenticeships in Welding

January-01-2018

Welding is a dangerous industry, and with there being various risks and hazards involved, it’s important to understand how these can be combated and the health and safety of employees protected. Here at Arc Welding Services, we are experienced in the welding industry, so we have detailed some of the most important aspects of… Continue reading The Risks Involved with Structural Welding

December-12-2017

An Introduction to the Arc Weld The arc weld is an integral aspect of construction and one of the most common welding processes used today, but what exactly is an arc weld? Well, since Arc Welding Services have a wealth of industry knowledge, we have put together this blog to run you through some of… Continue reading An Introduction to the Arc Weld

November-11-2017

If you’re reading this blog post, it’s fair to assume that you understand the basics of welding, but for those who don’t: welding is the process of joining two pieces of metal together by melting them at the intended joining point. A filler metal – or welding alloy – is utilised to blend with the… Continue reading Understanding Welding Alloys

October-10-2017

Welding is applied in a variety of different ways, all of which can require the adoption of a different position to carry out. Not every welding project is the same, so it’s important to ensure the right weld is used each time. Here at Arc Welding Services, we decided to run you through the main… Continue reading The Four Main Welding Positions

September-09-2017

Personal Protective Equipment, or PPE, is imperative in an industry such as welding, which presents incessant danger from the welding process that includes heat, radiation and ricochet. Here at Arc Welding Services, we understand the importance of health and safety, so we thought it best to kick off our “Health & Safety” series of blogs… Continue reading The PPE Required for the Welding Process

August-08-2017

Repairs and maintenance can be frustrating when working in any sector, and welding equipment repairs are no different. However, no matter how much of an inconvenience, these procedures are vital to maintaining the safety and performance of your equipment. Since we’re big fans of welding here at Arc Welding Services, we thought we’d outline… Continue reading The Importance of Welding Equipment Repairs

July-07-2017

What is Welding It’s funny, we’ve covered everything from underwater welding to outer-space welding, yet haven’t delved into the basics of the art itself. Speaking of art, we also discussed some of the most prominent welding artists in contemporary culture. However, this blog post details the basics of the industry on which this company, Arc… Continue reading What is Welding?

June-06-2017

Welding In Space: An Insight Into Cold Welding Let’s start with a simple science lesson: because there is no oxygen in space, creating sparks and lighting a fire is extremely difficult. Now for welding, sparks and fire are pretty essential. So what happens when repairs are needed 60-odd miles up in the air? This was… Continue reading Welding In Space: An Insight Into Cold Welding

April-04-2017

If you’re looking to start any welding projects, it’s imperative that you have the necessary welding equipment to begin your work. As leading welding experts in Birmingham, we know exactly all the equipment you’ll need to get your project completed. Welding can be seen as an intimidating job, using tools that will literally fuse two… Continue reading The Basic Welding Equipment You Need

March-03-2017

What is Underwater Welding? Underwater welding is a welding job that speaks for itself – welding underwater. It can also be known as hyperbaric welding, which defines the process of welding at elevated pressures. It is usually carried out wet and underwater or dry in enclosed positive pressure environments. Normally, steel is used for this… Continue reading What Is Underwater Welding?

March-03-2017

Top Welding Art and How To Make Your Own Welding these days isn’t just used by labourers in the industry; many people are trying their hand at creating welding art and are looking to take their skills to the next level. Welding is, put simply, just a form of creation – reshaping and forming pieces… Continue reading Top Welding Art And How To Make Your Own

March-03-2017

The History of Welding Welding is the process of creating a joint by fusing two pieces of metal structures together with a third piece of material. Usually, this process is carried out by heating the metal with a flame, an electric charge, or a laser light to melt or fuse the materials together. The history… Continue reading The History of Welding

March-03-2017

Working with metal and providing excellent welding services requires dexterity, practice, and skill. To be trusted and taken seriously in your profession, however, requires the adequate welding certification, which Arc Welding Services Ltd have explored below: Understand the different kind of welding processes available Novices to the industry may be surprised to learn that there… Continue reading What Welding Certification Do I Need?

March-03-2017

If you’re looking to start a successful welding career then providing you have the right skills and required certificates, the industry can be very rewarding. The employees within the industry are often changing and many more young people are heading into the welding industry. With such a well-sought after practical skill, embarking on a welding… Continue reading A Beginners Guide On Starting A Welding Career

March-03-2017

Welding Basics: The Different Types of Welding There are various different types of welding you’ll need to understand in order to get into the industry and begin your work. Working with metals and melting them into creations of art is something of a skill. Welding is no longer just joining two pieces of metal together,… Continue reading Welding Basics: The Different Types of Welding

March-03-2017

Protection Against Welding Safety Hazards Whenever you begin a new project your immediate consideration should be health and safety. Industrial work is hazardous, therefore it is imperative that you are aware of the risks around you and understand how to take the proper precautions to avoid injury. Arc Welding Services Ltd have highlighted below some… Continue reading Protection Against Welding Safety Hazards